Die casting is perhaps the most versatile and cost-effective production method, with a wider range of formats and elements than anyone else. Components have high durability and can be intended to support the nearby part’s aesthetic impact. By defining die-cast elements, creators could indeed gain numerous advantages as well as perks. Die casting individual components, decorative trim, as well as final goods provide numerous features, perks, and rewards to all those who choose the casting process as just a production line. There are amazing creators in Southeast Asia, so it is recommended to select the best southeast asia die casting company

What are some possible benefits?

- They are conveniently plated as well as completed and require little preparation.

- These could be made with substrates that simulate a wide range of contours.

- Coatings are clearer as modeled than in many other casting procedures such as sand, perpetual mold, and asset.

- Die casting gaps could be hollowed and managed to make to tap bore sizes.

- Components with exterior strands can be easily die cast.

- These provide essential adhesive bonding elements, like bosses as well as studs that can lead to assembly cost savings.

- Other materials as well as some inorganic materials could be die-cast in location as implants.

- Die casting metals have corrosion protection ranging from decent to elevated.

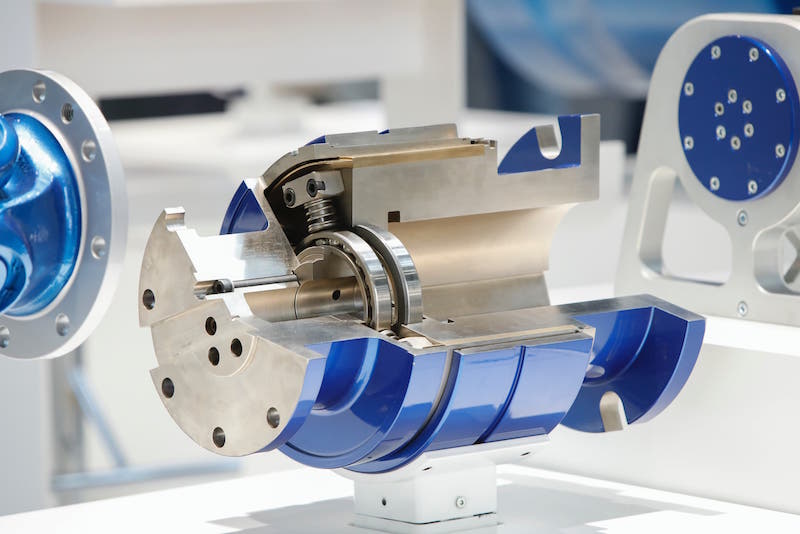

- Die castings are collective. They merge a variety of functions into a single, complexly shaped component. Even though die castings are not made up of different sections that are fused or pinned around each other, the toughness is what counts, not strands or rivets.

Disadvantages:

If there are so many advantages, there are some demerits as well. They are as follows:

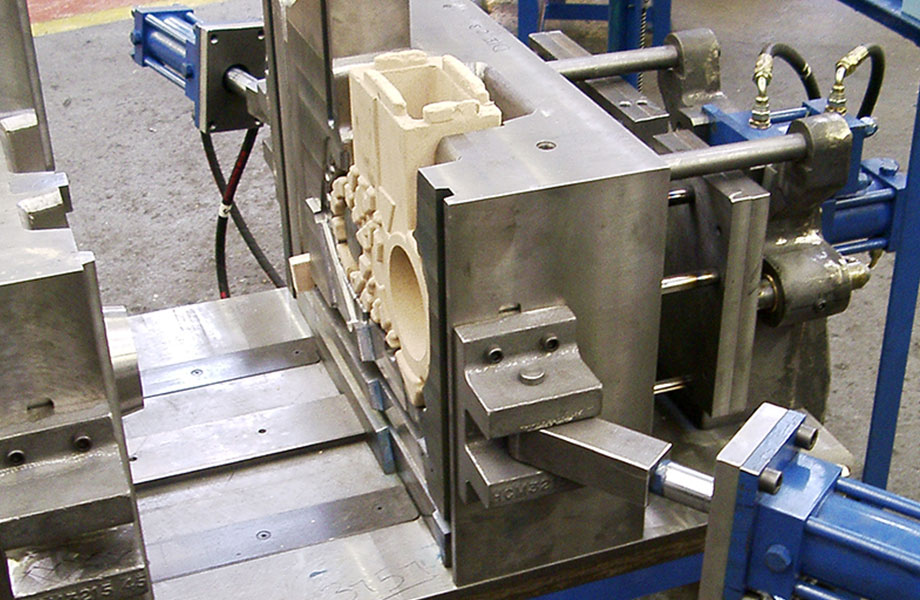

- Every mold must be accurately produced by hand, which takes too long of composing, influence, and formulate.

- Heaters must burn at temperatures in the thousands of degrees Fahrenheit, consuming expensive energy and emitting toxins that must be governed by an air purifier.

- The molding as well as forming hardware is accuracy engineered to handle the pressure of the combustion process.

- Just materials with great fluidity could be used, limiting the kinds of parts that can be manufactured.

- The procedure is generally controlled and maintained, particularly around the cooling stage.

- Die sets are made up of solid steel and are therefore not adjustable or changeable. They are exorbitantly priced.